Concept and design of application-specific motor topologies

The use of highly integrated mechatronic devices demanding more and more sophisticated characteristics for efficiency, noise, cost and reliability.

For thus, a FEM Design Process is applied, regarding the motor topology, the permanent magnetic flux, the inductance and the efficiency, by considering a cost efficient material selection (sintered, plastic molded, ceramic magnets). Also the analysis of existing custom motor designs and benchmarking contributes to improvements or improved adaptions. To validate the development results, self-manufactured prototypes for fast test purposes can be realized.

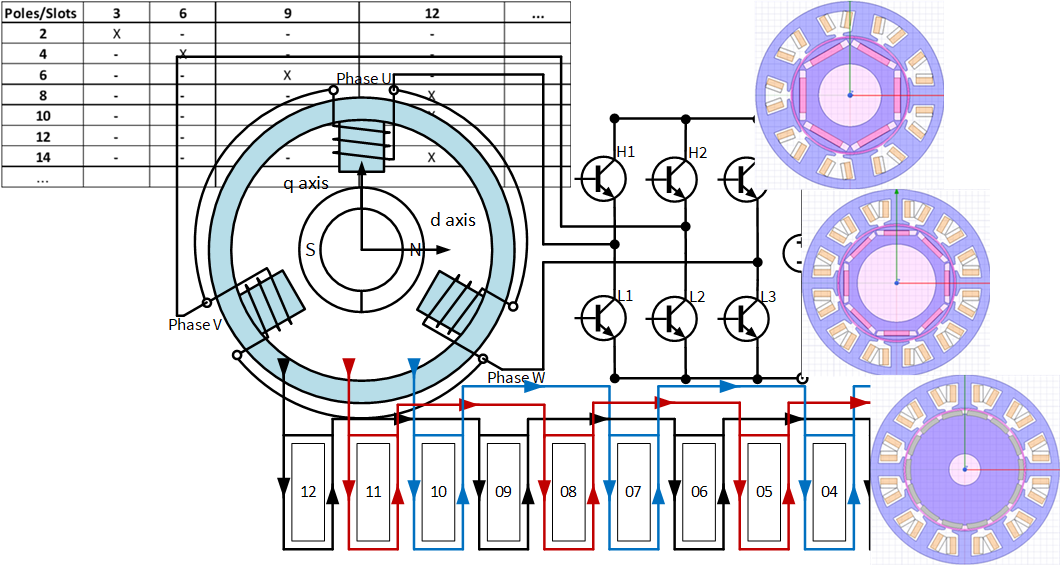

Motor Topology Concepts

- Determination of suitable motor principle, electrical phase system and commutation regime

- Evaluation of structural design - number of poles, number of coils, surface and integrated magnets, outer or inner runner

- Raw design simulations (FEM) for comparison and evaluation decisions

- Basic fundamental information for electronics development process

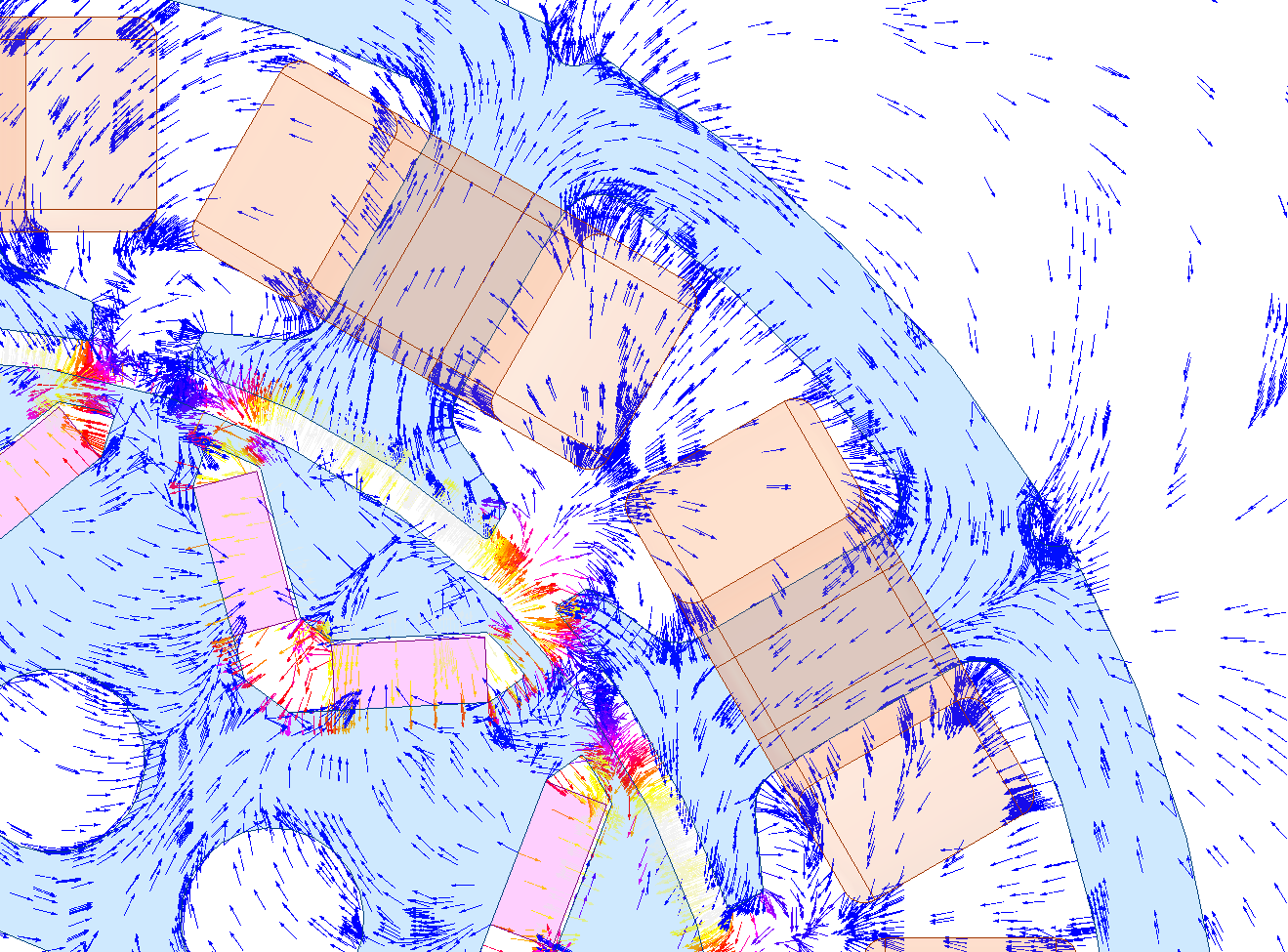

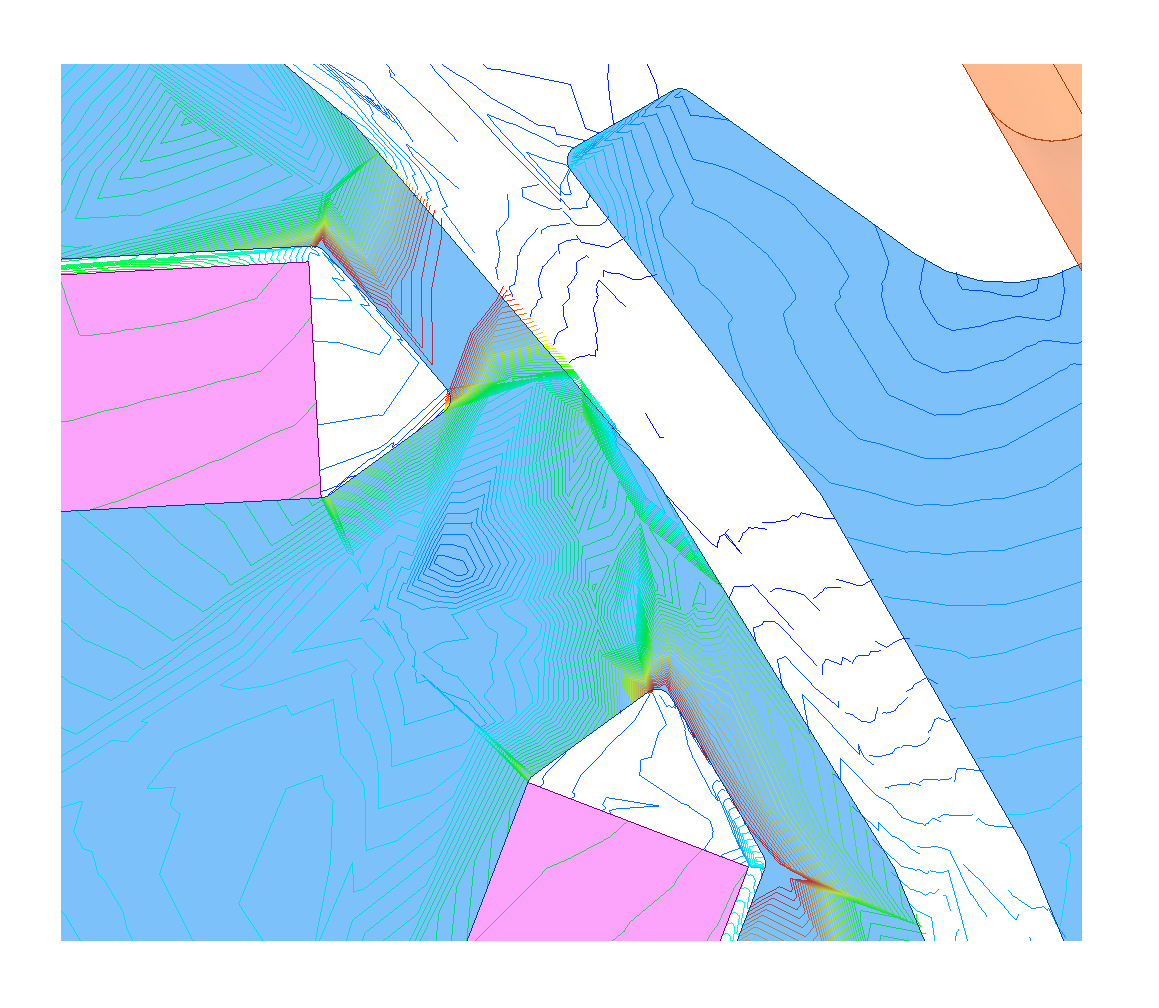

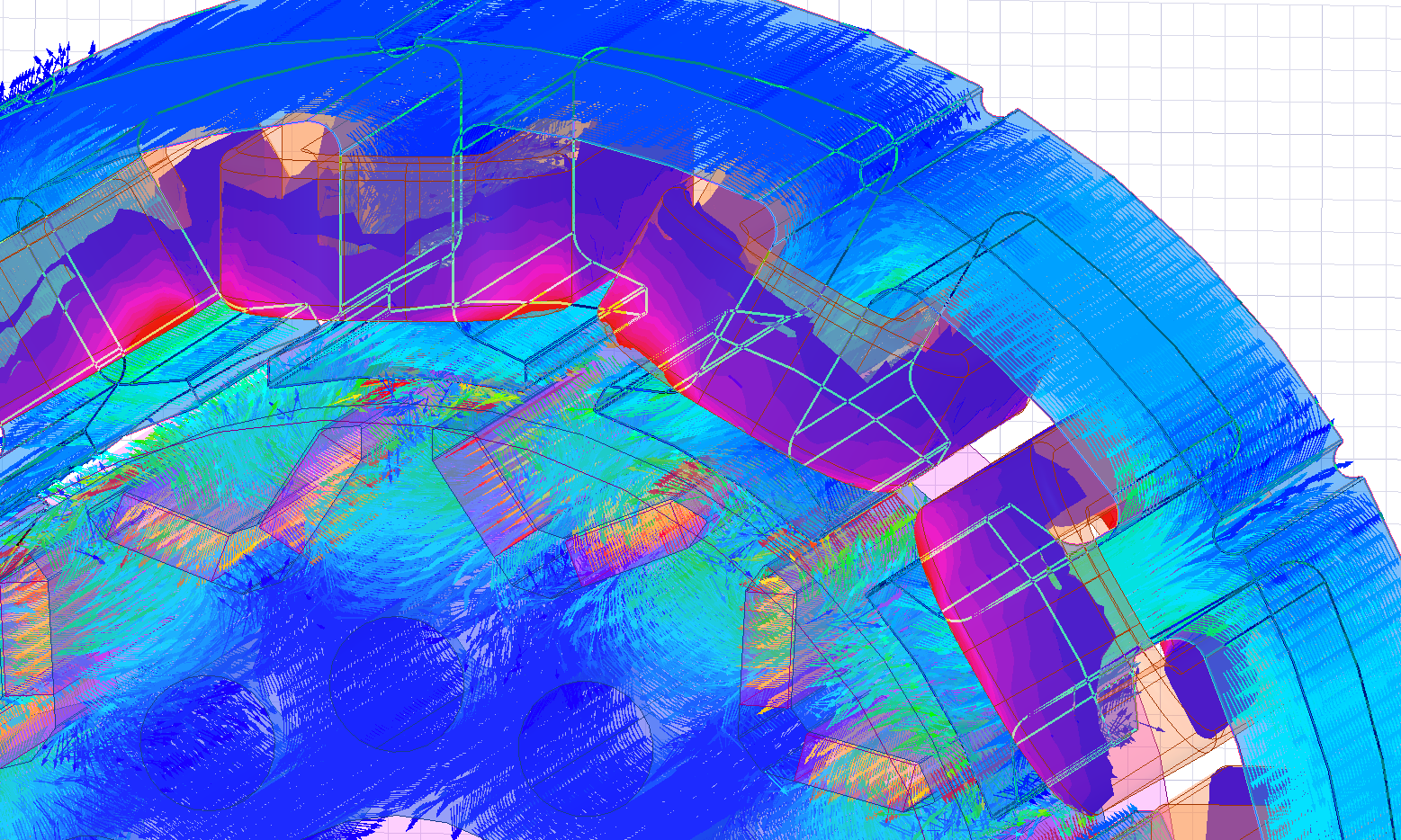

FEM Fine Dimensioning

- Optimization of the induced voltage shape or magnetic flux shape - adapting to commutation regime

- Shaping inductance characteristic to support or minimize reluctance force potential

- Fine dimensioning to match customers efficiency requirements in defined bandwidth

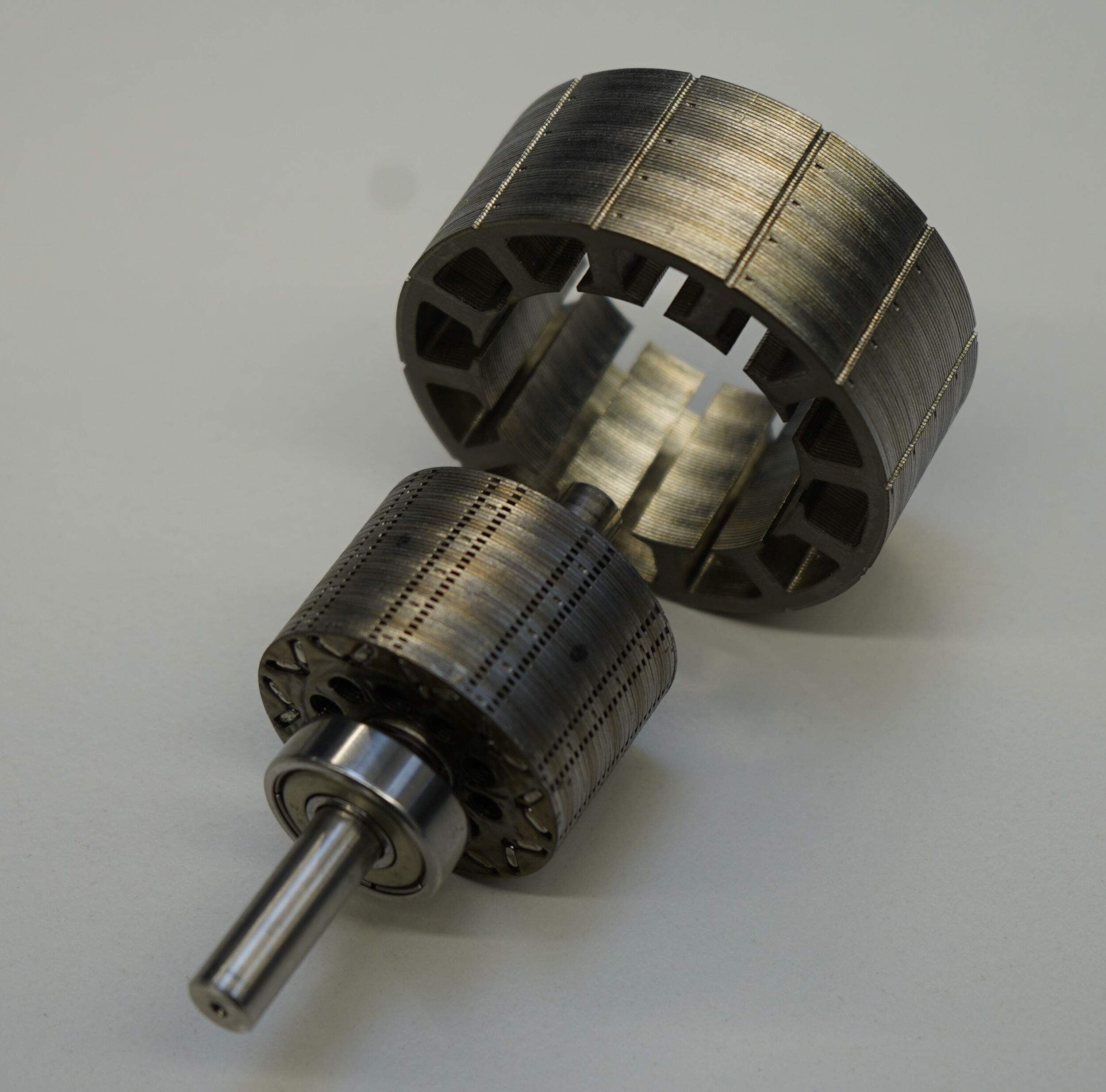

Prototyping

- CAD design of mechanical parts and supporting tools

- Manufacturing of motor assemblies, based on a network of reliable specialized suppliers (laminas, magnets, mechanical parts)

- Customized structural design and connection technology for specific requirements