Motor Test Bench

// The best way to test variety of motors and electronics.

Motor Test Bench (MTB)

The Motor Test Bench is designed to facilitate comprehensive testing and measurement of embedded systems, that generate mechanical rotary movement, as well as their components, ensuring their seamless development. With both automated and manual capabilities, the MTB empowers engineers to assess various functions and parameters, including mechanical and electrical characteristics, during the development and validation phases.

Some facts about the Motor Test Bench

Versatile testing capabilities (manual or automated)

Compliance with safety standards

Real time data tracing

High level communication with DUT

Your benefits at a glance

Motor Test Bench as a testing tool

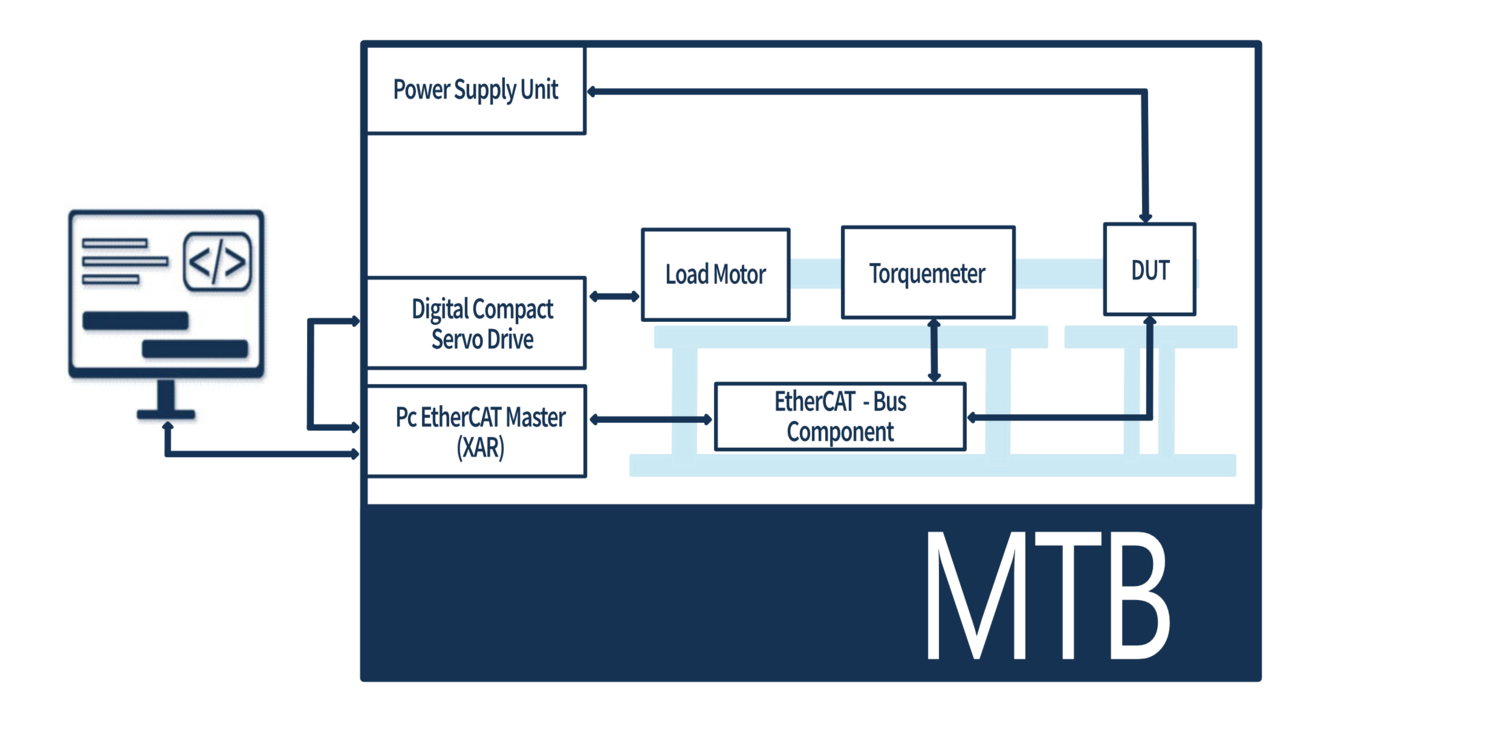

The Motor Test Bench is a device used to evaluate the performance of various types of motors, through measurement of the torque, speed, and power output of a motor, as well as its efficiency and other important parameters. This information can be used to optimize the design of a motor, to troubleshoot issues in it, or to assess the performance of a motor before it is installed in a larger system.

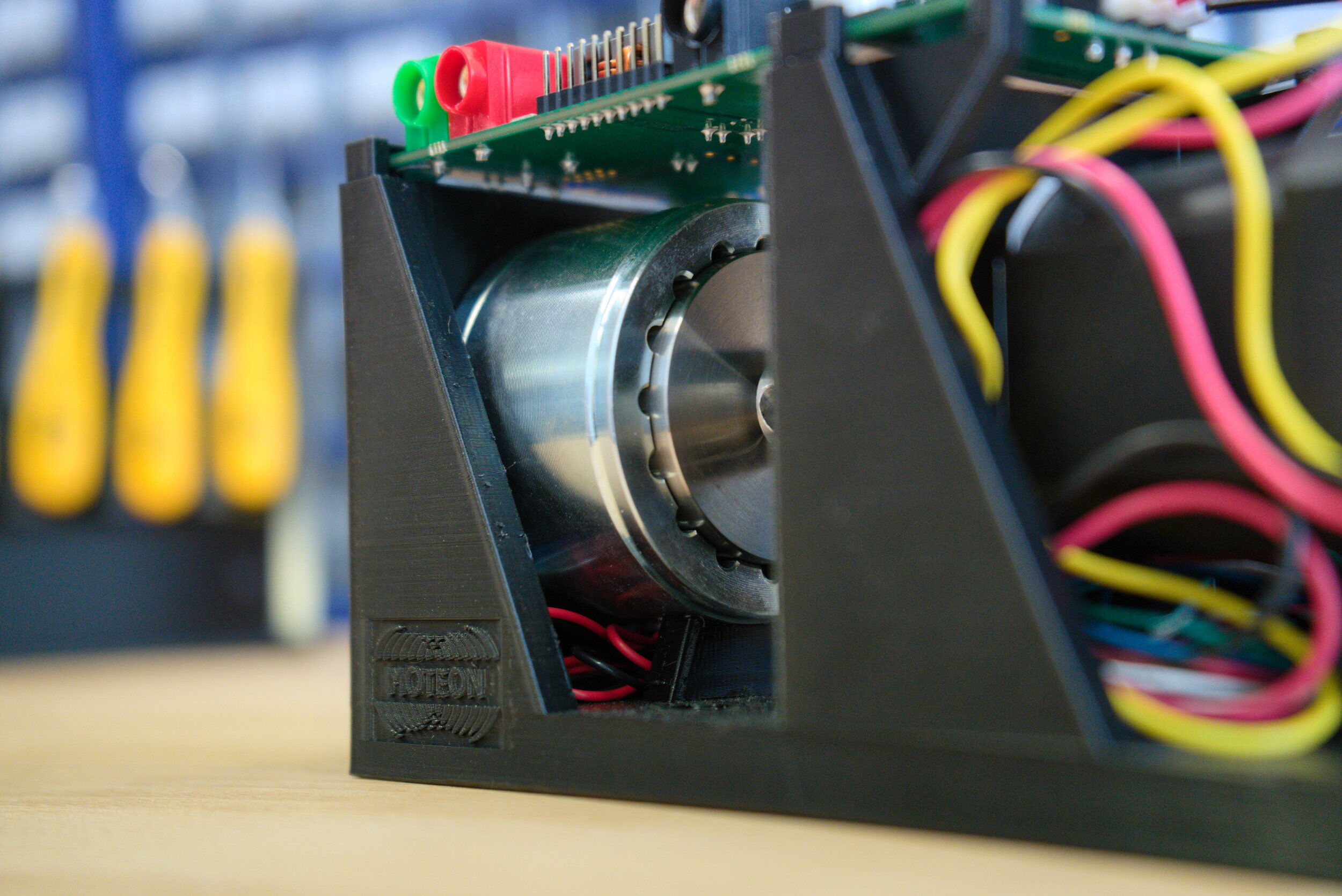

Deviating from the normal testing of motor and electronics separately. It is permissible to use an integrated DUT consisting of motor and electronics. This is then located completely in the mechanical test chamber.

The MTB offers coverage for testing and measuring the functions and parameters of embedded systems, analyzing mechanical and electrical characteristics, or evaluate mechatronic components during development. It is a versatile tool that can be used to perform these tasks effectively.

Its modular design allows for different performance classes, providing precise and reliable results across diverse applications.

Software integration (ECU-TEST) into existing ecosystems and into application lifecycle management.

Technical parameters

- Maximum continuous output power of 3.6 kW and maximum peak power of 4 kW

- High precision torque measurement with encoder resolution of 24 Bit

- Extensive safety protection with IP54 enclosure rating for electrical connection and an integrated safety controller

- Wide range of voltage supplies including 230 VAC and 440 VDC

Motor Test Bench

A test chamber is attached to the machine into which DUT (motors, optionally with integrated electronics) are placed. Load Motors (LM) are installed to measure the speed and to drive and brake the DUTs. The test chamber includes Load Motor, Torque measuring shaft and DUT. In a separate area next to the test chamber, E-DUTs and connection options are located to test electronic components.

Parametrics

Dimension with handles |

2040 x 1005 x 1775 mm |

Supply voltage MTB |

230 VAC (Max. 32 A) |

Shaft speed |

Max. 12.000 rpm |

Operating temperature |

15 ... 40 °C |